Shanghai SNOD Rubber Roller Manufacturing Co., Ltd.

Nuo QING ROLL MANUFACTURING (SHANGHAI) CO., LTD.

Address: No. 589 Fengyong Road, Qingcun Town Qinggang Industrial Park, Fengxian District, Shanghai

Zip code: 201414

Email: mail@m.a570.cn

Tel: +86-21-57569609

Fax: +86-21-57569659

Sales: +8613916373268

QQ: 2880099266

Rubber roll core

In addition to rubber material, the quality of roll core is also important for rubber rollers used under different conditions.

If the selection of roll core material and the design of mechanical structure are unreasonable, it may cause major problems in the use of rubber rollers.

Roller core materials are generally made of steel pipes, and stainless steel, aluminium and plastics are also used for special purposes.

In order to achieve lightweight roll in large roll body, more users use CFRP (Carbon Fiber Reinforced Plastic) and other composite materials as roll core.

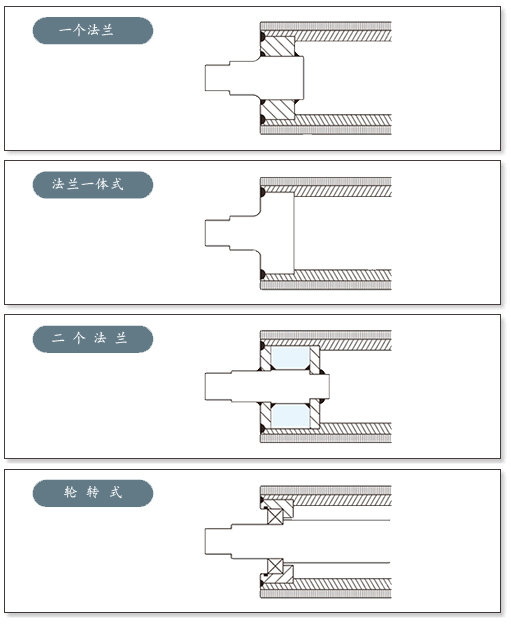

Roller core structure:

The figure above shows the common roll core structure.

Material forming roll core

Reasonable selection of roll core material is one of the important factors in cot manufacturing. Cot core usually uses metal materials, such as carbon steel, stainless steel, etc.

The following examples illustrate the representative material of the shaft, flange and roll core body which constitute the roll core.

Alloy tool steel| axis | Roll core | flange |

| Carbon tool steel | Rolled steel | Carbon steel pipes for piping |

| Alloy tool steel | CFRP Pipeline and GFRP Pipeline | CFRP Pipeline and GFRP Pipeline |

| Stainless steel | General purpose stainless steel | Carbon tool steel |

| Chromium-molybdenum cast steel | Stainless steel | |

| aluminum | aluminum |

Rubber Roll Balance

With the rapid development of the latest equipment, various accidents (such as vibration, noise, early wear of axles and bearings, early wear of gears, early damage of cots, early failure of machinery, etc.) occur due to the inappropriate balance of rollers.

These phenomena are caused by the rapid increase of centrifugal force due to unbalance as the roll body rotates upward.

The basic method of correcting the imbalance is usually to correct static and dynamic balances.

1. Static Balance

Static balance is a phenomenon caused by uneven load distribution of materials constituting the roll body.

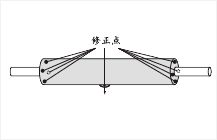

As shown in the figure, when the top rollers are supported by sharp corners, the heavy side will turn down. The amendment method is to reduce the weight of the lighter party or the heavier party.

2. Kinetic Balance

Dynamic balance occurs when the roll body rotates. The unbalance is expressed by the centrifugal force which makes the roll body swing in the same direction.

The method of dynamic balance and correction is to divide the surface of the roller into 360 equal parts and adjust the weight in the unbalanced position.

Balance of roll body is very important. When making roll core, static balance should be made according to the use and situation. But there is no customer's designation for dynamic balance, and it is generally not dynamic balance. Generally, the G6.3 level is recommended for 400m/min, and the G2.5 level is recommended for 400-1500m/min storage.